PP PE Protective Coverall: Enhancing Safety and Hygiene Across Industries

2025-12-23

In recent years, workplace safety and hygiene have become critical concerns across various industries, ranging from healthcare to chemical manufacturing and food processing. Among the essential protective equipment gaining prominence, the PP PE Protective Coverall has emerged as a versatile and reliable solution for safeguarding workers against environmental hazards. These coveralls, crafted from a combination of polypropylene (PP) and polyethylene (PE), offer a lightweight yet durable barrier against dust, liquids, and other contaminants, making them a go-to choice for many organizations worldwide.

The unique construction of PP PE Protective Coverall integrates the breathable properties of polypropylene with the chemical resistance of polyethylene. This dual-layer design ensures that while workers remain protected from harmful substances, they can also maintain comfort during prolonged usage. Unlike traditional protective garments that are often heavy and restrictive, these coveralls are designed to facilitate ease of movement, allowing personnel to perform tasks efficiently without compromising safety.

One of the primary applications of PP PE Protective Coverall is in the healthcare sector. Hospitals, clinics, and laboratories rely on these garments to protect medical staff from infectious agents, body fluids, and cross-contamination. During surgical procedures or patient care, healthcare professionals are exposed to various biological hazards. Wearing PP PE coveralls minimizes the risk of infection, ensuring both staff and patient safety. Moreover, their disposable nature helps maintain strict hygiene standards, preventing the spread of contaminants in sensitive environments.

Beyond healthcare, PP PE Protective Coverall plays a crucial role in the chemical and pharmaceutical industries. Workers handling corrosive liquids, powders, or hazardous chemicals require reliable protection to prevent skin contact and inhalation risks. The PE layer in the coverall provides a robust barrier against splashes and spills, while the PP layer ensures breathability, reducing discomfort associated with extended wear. This combination is especially valuable in manufacturing plants and laboratories where prolonged exposure to chemicals is common.

The food processing industry also benefits significantly from PP PE Protective Coverall. Maintaining hygiene standards is critical to ensure food safety and comply with regulatory requirements. Employees wearing these coveralls prevent hair, skin particles, and other contaminants from entering food products. Their lightweight and breathable design ensures that workers remain comfortable even in temperature-controlled environments, enhancing productivity while upholding stringent hygiene protocols.

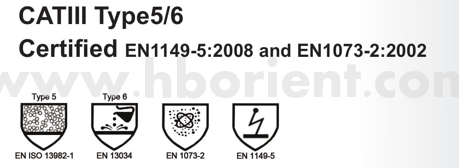

Safety regulations and standards further emphasize the importance of high-quality protective garments. Many PP PE Protective Coverall products are manufactured in compliance with international safety standards, ensuring consistent performance and reliability. Features such as elastic cuffs, ankles, and adjustable front zippers provide a secure fit, preventing exposure to harmful substances. Additionally, reinforced stitching and durable material enhance the coverall’s lifespan, making it a cost-effective investment for organizations seeking reliable protective wear.

Technological advancements in material science have also contributed to the evolution of PP PE Protective Coverall. Modern production techniques allow for the creation of multi-layer fabrics that offer improved tear resistance, liquid repellency, and breathability. Manufacturers are continuously innovating to provide garments that not only meet safety standards but also address the comfort and ergonomic needs of workers. As a result, the adoption of PP PE coveralls has expanded beyond traditional industrial applications to sectors such as electronics, automotive, and cleanroom operations.

Environmental considerations are becoming increasingly important in the selection of protective clothing. Many companies now prioritize disposable coveralls made from recyclable or biodegradable PP and PE materials, reducing the environmental impact while maintaining safety standards. This aligns with global sustainability goals and demonstrates a commitment to responsible manufacturing practices.

In conclusion, PP PE Protective Coverall has proven to be a versatile, reliable, and essential protective garment across multiple industries. Its combination of durability, breathability, and chemical resistance ensures that workers are safeguarded from a wide range of hazards without compromising comfort or mobility. From healthcare and food processing to chemical manufacturing and cleanroom operations, these coveralls provide peace of mind and reinforce workplace safety standards. As industries continue to prioritize worker protection and hygiene, the demand for high-quality PP PE Protective Coverall is expected to grow, solidifying its role as a cornerstone of personal protective equipment worldwide.

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation