Understanding the Material Composition of Type 3B Coveralls: The Ultimate Guide

2025-11-07

Understanding the Material Composition of Type 3B Coveralls

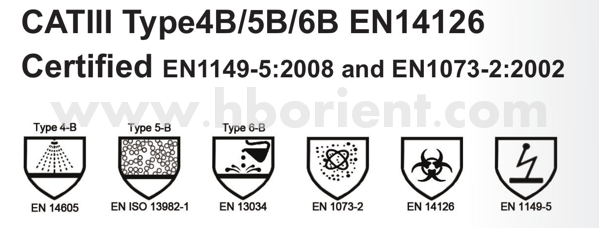

In industries where hazardous materials are present, the right protective equipment is crucial. Among the various protective gear available, Type 3B coveralls stand out for their effectiveness in safeguarding against liquid chemicals and biological hazards. This article delves into the material composition of Type 3B coveralls, helping you understand their properties, advantages, and best practices for use.

The Importance of Protective Clothing in Hazardous Environments

Protective clothing serves as a barrier between the wearer and potential threats in hazardous environments. These threats can range from chemical spills to infectious agents. Type 3B coveralls are engineered to prevent liquid penetration, ensuring that workers remain safe and comfortable while performing their duties.

What Are Type 3B Coveralls?

Type 3B coveralls are a specific category of protective clothing designed to provide a high level of protection against liquid chemicals. They are often used in industries such as healthcare, laboratory environments, and sanitation services. With a focus on preventing liquid penetration, Type 3B coveralls are essential for workers exposed to harmful substances.

Key Features of Type 3B Coveralls

The effectiveness of Type 3B coveralls can be attributed to several key features:

1. **Liquid Barrier**: Made from waterproof materials, these coveralls prevent liquids from reaching the skin.

2. **Breathability**: Despite their liquid barrier properties, Type 3B coveralls are designed to allow moisture vapor to escape, reducing discomfort during extended wear.

3. **Durability**: Constructed from high-quality materials, these coveralls offer resistance to wear and tear, ensuring longevity even in rigorous working conditions.

Material Composition of Type 3B Coveralls

Understanding the materials used in Type 3B coveralls is essential for grasping their protective capabilities. The primary materials include:

1. Polyethylene (PE)

Polyethylene is a common material used in Type 3B coveralls due to its excellent chemical resistance and waterproof properties.

- **Benefits**: PE offers a lightweight solution that does not compromise on durability, making it ideal for prolonged use.

- **Applications**: Commonly found in medical and laboratory settings, PE coveralls are effective against various chemical spills.

2. Polypropylene (PP)

Another key material is polypropylene, known for its strength and resistance to various chemicals.

- **Benefits**: PP is breathable, allowing for comfort during extended wear while providing a solid barrier against liquid hazards.

- **Applications**: Frequently used in agricultural applications and hazardous waste clean-up.

3. Polyurethane (PU)

Polyurethane is often used in conjunction with other materials to enhance flexibility and overall wearability.

- **Benefits**: PU-coated fabrics provide a high degree of flexibility, making movements easier for the wearer while still offering chemical resistance.

- **Applications**: Ideal for environments where mobility is essential, such as in emergency response situations.

How Material Composition Affects Performance

The specific combination of materials in Type 3B coveralls significantly influences their performance in various environments.

1. Chemical Resistance

Different chemicals require specific materials for effective protection. The right combination of PE, PP, and PU ensures that workers are safeguarded against a wide range of hazardous substances.

2. Breathability and Comfort

The choice of materials directly impacts breathability. Workers in high-temperature environments benefit from breathable fabrics, reducing the risk of heat stress during prolonged wear.

3. Durability and Cost-Effectiveness

Investing in high-quality Type 3B coveralls composed of durable materials can lead to long-term savings, as they are less likely to require frequent replacements.

Choosing the Right Type 3B Coveralls

When selecting Type 3B coveralls, several factors must be considered to ensure optimal protection and comfort.

1. Assessing the Hazard Level

Understanding the specific hazards present in your working environment is crucial. Different chemicals may require different levels of protection, so always assess the risks before making a decision.

2. Fit and Comfort

A proper fit enhances both safety and comfort. Ensure that the coveralls allow for adequate movement without being overly loose or restrictive.

3. Features and Customization

Look for additional features such as adjustable hoods, cuffs, and ankle closures. Customized options can provide a better fit and added protection based on specific job requirements.

Best Practices for Using Type 3B Coveralls

To maximize the effectiveness of Type 3B coveralls, adhering to best practices is essential.

1. Proper Donning and Doffing

Ensure that workers are trained in the correct procedures for putting on and taking off coveralls to minimize contamination risks.

2. Regular Inspections

Conduct routine inspections of coveralls for signs of wear and damage. Replace any compromised garments immediately to maintain safety standards.

3. Cleaning and Maintenance

Understand the cleaning requirements for your specific coveralls. Some may be disposable, while others can be laundered and reused. Always follow the manufacturer’s guidelines.

Frequently Asked Questions (FAQs)

1. What is the difference between Type 3B and Type 4 coveralls?

Type 3B coveralls are designed for liquid penetration while Type 4 coveralls provide protection against splashes and sprays of hazardous liquids.

2. Can Type 3B coveralls be reused?

Some Type 3B coveralls are designed for single-use, while others can be washed and reused. Always refer to the manufacturer's instructions.

3. What environments are Type 3B coveralls suitable for?

These coveralls are ideal for medical settings, laboratories, and situations involving hazardous materials or chemical spills.

4. How do I ensure a proper fit for Type 3B coveralls?

To ensure a proper fit, check the sizing charts provided by manufacturers and consider trying them on before purchase when possible.

5. Are there specific cleaning methods for Type 3B coveralls?

Cleaning methods can vary based on the materials used. Always follow the specific care instructions provided by the manufacturer.

Conclusion

In conclusion, understanding the material composition of Type 3B coveralls is essential for anyone involved in industries where hazardous materials are present. From the protective capabilities of polyethylene and polypropylene to the importance of breathability and durability, each aspect plays a vital role in ensuring safety and comfort. By choosing the right coveralls and following best practices, workers can significantly enhance their protection against liquid hazards. Make informed decisions to create a safer working environment, prioritizing both safety and comfort in your protective gear choices.

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation