Understanding Type 3B Coveralls: Essential Protective Gear for Various Industries

2025-10-13

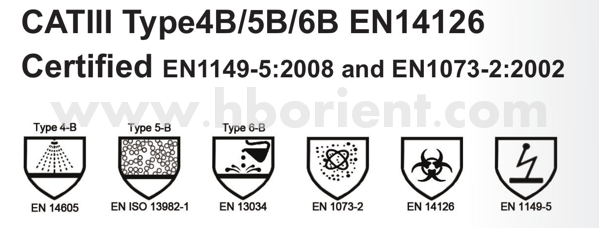

Type 3B coveralls are an essential component of personal protective equipment (PPE) designed to safeguard workers in various industries, particularly those involved in cleaning and sanitation tasks. These coveralls are specifically engineered to offer a high level of protection against airborne contaminants, liquids, and chemical substances. Understanding the features and applications of Type 3B coveralls can greatly enhance workplace safety and health.

One of the primary characteristics of Type 3B coveralls is their resistance to liquid penetration. They are made from specialized materials that prevent the ingress of water and other liquids, making them suitable for environments where exposure to such substances is a concern. This feature is particularly important in the cleaning industry, where workers often handle hazardous chemicals and liquids that can pose health risks.

Additionally, Type 3B coveralls provide a barrier against solid particles and contaminants. This is crucial for professionals who frequently interact with substances that can lead to respiratory issues or skin irritations. By wearing these protective garments, workers can minimize their risk of exposure to harmful agents, ultimately contributing to a safer workplace.

Another significant aspect of Type 3B coveralls is their design, which often includes features such as hoods, elastic cuffs, and reinforced seams. These elements work together to ensure a snug fit and enhance the overall protective capabilities of the coveralls. Properly fitted coveralls are essential for maximizing the effectiveness of PPE; any gaps or loose areas may compromise protection and increase the risk of exposure.

In the context of light industry and cleaning supplies, Type 3B coveralls serve a broader purpose beyond just individual safety. They play a crucial role in maintaining cleanliness and hygiene standards, especially in environments like hospitals, laboratories, and food processing facilities. Using appropriate protective clothing helps prevent cross-contamination and ensures that operations remain compliant with health and safety regulations.

Moreover, the importance of training and education about the correct use of Type 3B coveralls cannot be overstated. Workers should be aware not only of the appropriate circumstances for wearing these coveralls but also of how to don and doff them safely. Proper usage ensures that the protective features of the coveralls are fully realized, further enhancing worker safety.

In conclusion, Type 3B coveralls are a vital aspect of personal protective equipment that offers significant protection against liquid and solid contaminants. Their role in promoting safety in the workplace, particularly in the light industry and cleaning sectors, cannot be overlooked. By understanding and utilizing these coveralls effectively, businesses can protect their employees, uphold safety standards, and promote a culture of health and safety within their operations.

One of the primary characteristics of Type 3B coveralls is their resistance to liquid penetration. They are made from specialized materials that prevent the ingress of water and other liquids, making them suitable for environments where exposure to such substances is a concern. This feature is particularly important in the cleaning industry, where workers often handle hazardous chemicals and liquids that can pose health risks.

Additionally, Type 3B coveralls provide a barrier against solid particles and contaminants. This is crucial for professionals who frequently interact with substances that can lead to respiratory issues or skin irritations. By wearing these protective garments, workers can minimize their risk of exposure to harmful agents, ultimately contributing to a safer workplace.

Another significant aspect of Type 3B coveralls is their design, which often includes features such as hoods, elastic cuffs, and reinforced seams. These elements work together to ensure a snug fit and enhance the overall protective capabilities of the coveralls. Properly fitted coveralls are essential for maximizing the effectiveness of PPE; any gaps or loose areas may compromise protection and increase the risk of exposure.

In the context of light industry and cleaning supplies, Type 3B coveralls serve a broader purpose beyond just individual safety. They play a crucial role in maintaining cleanliness and hygiene standards, especially in environments like hospitals, laboratories, and food processing facilities. Using appropriate protective clothing helps prevent cross-contamination and ensures that operations remain compliant with health and safety regulations.

Moreover, the importance of training and education about the correct use of Type 3B coveralls cannot be overstated. Workers should be aware not only of the appropriate circumstances for wearing these coveralls but also of how to don and doff them safely. Proper usage ensures that the protective features of the coveralls are fully realized, further enhancing worker safety.

In conclusion, Type 3B coveralls are a vital aspect of personal protective equipment that offers significant protection against liquid and solid contaminants. Their role in promoting safety in the workplace, particularly in the light industry and cleaning sectors, cannot be overlooked. By understanding and utilizing these coveralls effectively, businesses can protect their employees, uphold safety standards, and promote a culture of health and safety within their operations.

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation