Microporous Film Laminates vs. Traditional Materials: What’s Better for Coveralls?

2025-09-08

Microporous Film Laminates vs. Traditional Materials: What’s Better for Coveralls?

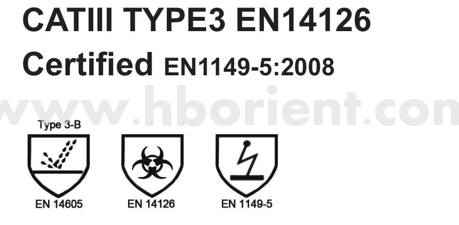

In industries where safety and protection are paramount, coveralls play a crucial role in safeguarding workers from hazardous materials, chemicals, and environmental contaminants. While several materials are available for manufacturing these protective garments, two of the most discussed options are microporous film laminates and traditional fabrics. This article delves deep into the advantages and disadvantages of each, providing comprehensive insights to help you make an informed decision.

Understanding Coveralls: Purpose and Applications

Coveralls are essential personal protective equipment (PPE) used in various industries, including construction, manufacturing, healthcare, and agriculture. Their primary purpose is to protect the wearer's body from hazards such as chemicals, biological agents, and physical irritants.

The Role of Coveralls in Workplace Safety

Coveralls serve multiple functions in a workplace setting:

- They provide a barrier against hazardous substances.

- They minimize the risk of contamination.

- They enhance comfort and mobility for workers.

What are Microporous Film Laminates?

Microporous film laminates are innovative materials composed of multiple layers, featuring a microporous membrane that allows moisture vapor to escape while preventing liquid penetration. This unique structure offers high levels of breathability and protection, making them a popular choice for coveralls in various industries.

Key Features of Microporous Film Laminates

- Breathability: The microporous structure facilitates moisture vapor transmission, keeping the wearer dry and comfortable.

- Liquid Resistance: They provide an effective barrier against liquids, protecting against spills and splashes.

- Durability: These laminates are designed to withstand wear and tear, ensuring long-lasting performance.

- Lightweight: Compared to traditional fabrics, microporous film laminates are typically lighter, enhancing mobility.

What are Traditional Materials in Coveralls?

Traditional materials often used in coveralls include cotton, polyester, and blends thereof. These materials have been utilized in protective clothing for many years and come with their own set of characteristics that may appeal to specific user needs.

Characteristics of Traditional Materials

- Comfort: Natural fibers like cotton provide excellent comfort and softness against the skin.

- Breathability: Traditional fabrics typically offer good airflow, although not as effectively as microporous laminates.

- Affordability: Traditional materials are often more cost-effective, making them an attractive option for budget-conscious employers.

- Versatility: These materials are available in various styles and can be used across different settings.

Comparative Analysis: Microporous Film Laminates vs. Traditional Materials

Protection Against Hazards

When it comes to protection, microporous film laminates significantly outperform traditional materials. Their ability to repel liquids while allowing vapor to escape ensures that workers remain safe from hazardous chemical exposure. In contrast, traditional cotton and polyester fabrics may absorb liquids, increasing the risk of contamination.

Comfort and Wearability

Comfort is critical for long-term wear, especially in demanding environments. While traditional materials excel in providing a soft, breathable experience, microporous film laminates have made strides in this area as well. Advanced designs ensure that wearers of laminated coveralls can enjoy enhanced comfort through moisture management, even during extended use.

Durability and Longevity

In terms of durability, microporous film laminates often last longer than traditional materials. They resist abrasions, tears, and other forms of wear, making them suitable for rugged environments. Traditional fabrics, while comfortable, may show signs of wear more quickly when exposed to harsh conditions.

Cost Considerations

Cost is always a factor in decision-making. Traditional materials are generally less expensive, making them appealing for large-scale purchases. However, the higher initial investment in microporous film laminates can be justified by their longevity and superior protective qualities, potentially reducing replacement costs over time.

Industry-Specific Considerations

Healthcare and Medical Applications

In healthcare settings, the need for protection is critical. Microporous film laminates are often preferred due to their liquid barrier properties and breathability. They are commonly used in medical coveralls and gowns, ensuring that healthcare professionals remain safe from contamination.

Industrial and Manufacturing Environments

In industrial settings, coveralls must withstand exposure to chemicals and physical hazards. Microporous film laminates provide a superior level of protection, making them ideal for workers handling hazardous materials. Traditional fabrics may be more suitable for environments with less exposure to harmful substances.

Agricultural Use

In agriculture, workers often face exposure to pesticides and chemicals. Microporous film laminates offer an excellent barrier against these harmful agents while allowing for breathability, making them a popular choice among farmers and agricultural workers.

Frequently Asked Questions (FAQs)

1. Are microporous film laminates waterproof?

Microporous film laminates are not entirely waterproof; however, they provide excellent resistance to liquid penetration while allowing vapor to escape, making them suitable for various applications.

2. How do I choose the right coverall material for my needs?

Consider factors such as the level of protection required, work environment, comfort, and budget. Microporous film laminates are ideal for hazardous environments, while traditional materials may suffice for less risky tasks.

3. Can traditional materials be treated to improve their protective qualities?

Yes, traditional materials can be treated with water-repellent coatings or other chemicals to enhance their protective qualities, but they may still not match the performance of microporous film laminates.

4. How do I maintain and care for my coveralls?

Follow the manufacturer's care instructions for washing and drying. Generally, avoid using harsh chemicals that could degrade the material and compromise protective properties.

5. Are there any environmental concerns with microporous film laminates?

While microporous film laminates are effective in providing protection, their production may have environmental impacts. Consider sourcing products from manufacturers committed to sustainable practices and recycling programs.

Conclusion

Choosing the right material for coveralls is a crucial decision that affects worker safety, comfort, and overall efficiency. Microporous film laminates offer unparalleled protection against hazardous materials, liquids, and contaminants while providing breathability and durability. While traditional materials have their merits and may be more budget-friendly, they fall short in high-risk environments. In the end, assessing your specific needs, including workplace conditions and safety requirements, will guide you in selecting the best coverall material for your situation.

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation