Understanding Microporous Film Laminates in Coveralls: A Comprehensive Guide

2025-08-14

---

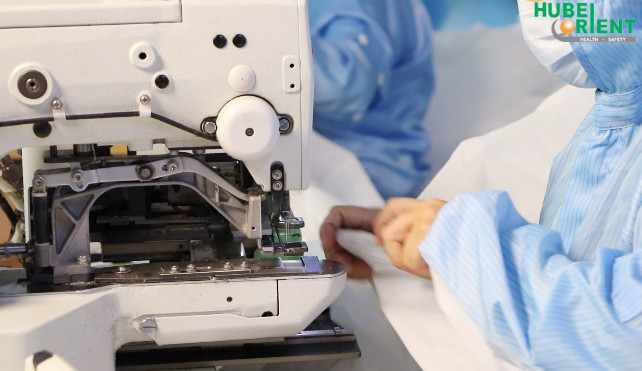

Microporous film laminates are a sophisticated material choice in the manufacturing of coveralls, particularly in industries where hygiene and protection are paramount. These laminates are engineered to feature a microporous structure, meaning they possess tiny pores that allow moisture vapor to escape while blocking larger liquid droplets and particulate matter. This unique combination creates a barrier that is both breathable and protective, making it an ideal material for personal protective equipment (PPE) in various settings.

The primary advantage of using microporous film laminates in coveralls is their ability to provide excellent protection against liquids and hazardous substances while maintaining comfort for the wearer. This is especially crucial in sectors such as healthcare, food processing, and industrial cleaning, where exposure to contaminants can pose significant health risks. The breathable nature of these laminates helps to regulate body temperature and reduce the likelihood of perspiration, thus ensuring that personnel can perform their tasks without discomfort.

Another important aspect of microporous film laminates is their lightweight design. Unlike traditional protective materials that can be cumbersome, garments made from these laminates allow for greater freedom of movement, making them suitable for prolonged wear. This is especially beneficial in environments that require dexterity and agility, as workers can carry out their responsibilities more efficiently without being hindered by heavy or restrictive clothing.

Moreover, microporous film laminates are often resistant to a variety of chemicals and biological agents, which enhances their effectiveness in preventing contamination. This characteristic is crucial in maintaining hygiene standards in settings such as hospitals and laboratories, where exposure to pathogens can occur. The protective capabilities of these materials ensure that they serve as a reliable barrier, reducing the risk of cross-contamination and enhancing overall safety.

In addition to their functional benefits, coveralls made from microporous film laminates can also be designed with user comfort in mind. Features such as elastic cuffs, adjustable hoods, and breathable panels can further enhance the fit and feel of the garment, making them suitable for a wide range of applications. This adaptability is key in ensuring that workers remain protected while also feeling comfortable in their attire.

In summary, microporous film laminates play a vital role in the production of coveralls used across various industries. Their ability to combine breathability with protection against liquids and particulates makes them an excellent choice for professionals needing reliable safety gear. As awareness of hygiene and safety continues to grow, the importance of such innovative materials in the realm of personal protective equipment cannot be overstated. Emphasizing comfort, flexibility, and protection, microporous film laminates represent a significant advancement in the design of coveralls for hygienic and clean environments.

Microporous film laminates are a sophisticated material choice in the manufacturing of coveralls, particularly in industries where hygiene and protection are paramount. These laminates are engineered to feature a microporous structure, meaning they possess tiny pores that allow moisture vapor to escape while blocking larger liquid droplets and particulate matter. This unique combination creates a barrier that is both breathable and protective, making it an ideal material for personal protective equipment (PPE) in various settings.

The primary advantage of using microporous film laminates in coveralls is their ability to provide excellent protection against liquids and hazardous substances while maintaining comfort for the wearer. This is especially crucial in sectors such as healthcare, food processing, and industrial cleaning, where exposure to contaminants can pose significant health risks. The breathable nature of these laminates helps to regulate body temperature and reduce the likelihood of perspiration, thus ensuring that personnel can perform their tasks without discomfort.

Another important aspect of microporous film laminates is their lightweight design. Unlike traditional protective materials that can be cumbersome, garments made from these laminates allow for greater freedom of movement, making them suitable for prolonged wear. This is especially beneficial in environments that require dexterity and agility, as workers can carry out their responsibilities more efficiently without being hindered by heavy or restrictive clothing.

Moreover, microporous film laminates are often resistant to a variety of chemicals and biological agents, which enhances their effectiveness in preventing contamination. This characteristic is crucial in maintaining hygiene standards in settings such as hospitals and laboratories, where exposure to pathogens can occur. The protective capabilities of these materials ensure that they serve as a reliable barrier, reducing the risk of cross-contamination and enhancing overall safety.

In addition to their functional benefits, coveralls made from microporous film laminates can also be designed with user comfort in mind. Features such as elastic cuffs, adjustable hoods, and breathable panels can further enhance the fit and feel of the garment, making them suitable for a wide range of applications. This adaptability is key in ensuring that workers remain protected while also feeling comfortable in their attire.

In summary, microporous film laminates play a vital role in the production of coveralls used across various industries. Their ability to combine breathability with protection against liquids and particulates makes them an excellent choice for professionals needing reliable safety gear. As awareness of hygiene and safety continues to grow, the importance of such innovative materials in the realm of personal protective equipment cannot be overstated. Emphasizing comfort, flexibility, and protection, microporous film laminates represent a significant advancement in the design of coveralls for hygienic and clean environments.

Next —

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation