A Comprehensive Guide to Selecting the Right Type 3B Coveralls

2025-06-10

A Comprehensive Guide to Selecting the Right Type 3B Coveralls

Type 3B coveralls are essential for professionals working in environments where protection from hazardous substances is paramount. These coveralls provide a barrier against liquid chemicals, making them indispensable in various industries such as healthcare, manufacturing, and cleaning services. In this guide, we will delve into the characteristics, benefits, and selection criteria for Type 3B coveralls, ensuring you make an informed decision.

Table of Contents

- Understanding Type 3B Coveralls

- Key Features of Type 3B Coveralls

- Different Materials Used in Coveralls

- Applications of Type 3B Coveralls

- How to Select the Right Type 3B Coveralls

- Maintenance and Care of Type 3B Coveralls

- Common Misconceptions About Type 3B Coveralls

- Frequently Asked Questions

- Conclusion

Understanding Type 3B Coveralls

Type 3B coveralls are part of a broader classification system that categorizes protective clothing based on the level of protection they offer. These coveralls are designed specifically to protect against liquid chemicals while maintaining comfort and mobility. The designation "Type 3B" indicates that these garments meet stringent performance standards for liquid penetration resistance.

Employers must equip their workforce with appropriate personal protective equipment (PPE), and Type 3B coveralls are a key component in safeguarding employees from hazardous substances. The correct use of these coveralls can significantly reduce the risk of chemical exposure and injury.

Key Features of Type 3B Coveralls

When selecting Type 3B coveralls, it is essential to understand their key features, which include:

1. Liquid Resistance

The primary function of Type 3B coveralls is to provide a barrier against liquid chemicals. They are designed to withstand exposure to various liquids, ensuring that workers remain safe during their tasks.

2. Breathability

While protection is crucial, coveralls must also be breathable to prevent overheating and ensure comfort during extended wear. Look for materials that offer breathability without compromising on liquid resistance.

3. Comfort and Fit

A well-fitting coverall not only enhances mobility but also reduces the risk of contamination. Ensure that the coveralls allow for ease of movement while providing a secure fit.

4. Durability

Type 3B coveralls should be constructed from high-quality materials that can withstand wear and tear. Durability is an essential feature, especially in industrial settings where coveralls face challenging conditions.

5. Visibility Features

In some applications, high visibility is crucial for safety. Many Type 3B coveralls come with reflective strips or bright colors to enhance the visibility of workers in low-light conditions.

Different Materials Used in Coveralls

The materials used in Type 3B coveralls play a significant role in their performance. Here are some commonly used materials:

1. Polyethylene

Polyethylene is a lightweight material known for its excellent liquid resistance. It is often used in disposable coveralls, making it a cost-effective choice for industries where containment is a priority.

2. Tyvek®

Tyvek® is a brand of flash-spun high-density polyethylene fibers that are breathable and resistant to a wide range of chemicals. Tyvek® coveralls provide a good balance between protection and comfort.

3. PVC Coated Fabrics

PVC (polyvinyl chloride) coated fabrics are highly durable and resistant to various chemicals. These coveralls are suitable for tasks that involve heavy-duty cleaning or exposure to harsh substances.

Applications of Type 3B Coveralls

Type 3B coveralls are versatile and used across various industries, including:

1. Healthcare

In healthcare environments, Type 3B coveralls protect healthcare workers from bloodborne pathogens and other hazardous materials during procedures.

2. Chemical Manufacturing

Workers in chemical plants often handle dangerous liquids. Type 3B coveralls are crucial to safeguarding them from chemical exposure.

3. Cleaning Services

Cleaning professionals frequently encounter hazardous materials. Wearing Type 3B coveralls ensures they are protected while carrying out their duties.

How to Select the Right Type 3B Coveralls

Selecting the right Type 3B coveralls involves several considerations:

1. Assess the Risks

Identify the specific risks associated with the tasks your workforce will perform. Understand what types of chemicals they may encounter to ensure the coveralls provide adequate protection.

2. Consider the Environment

The working environment plays a crucial role in your choice. Evaluate factors such as temperature, humidity, and the potential for physical hazards.

3. Evaluate Comfort and Fit

Mismatched sizes can lead to discomfort and decreased mobility. Ensure that the coveralls fit well and allow for easy movement. Consider adjustable features such as cuffs, waistbands, and hoods.

4. Seek Certifications

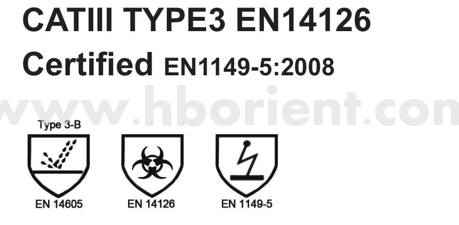

Verify that the coveralls meet relevant safety standards, such as ASTM or EN certifications. These ensure that the coveralls have been tested and meet specific performance criteria.

Maintenance and Care of Type 3B Coveralls

Proper maintenance extends the life of Type 3B coveralls and ensures they provide the necessary protection. Here are some tips:

1. Follow Manufacturer Instructions

Always refer to the manufacturer's care instructions to avoid damaging the coveralls. Specific guidelines will outline proper cleaning and storage practices.

2. Regular Inspections

Conduct regular inspections for signs of wear and tear. Check for rips, tears, or signs of chemical exposure, and replace coveralls as necessary.

3. Store Properly

Store coveralls in a clean, dry area away from direct sunlight to prevent degradation of materials. Proper storage prolongs their lifespan and maintains their protective qualities.

Common Misconceptions About Type 3B Coveralls

Understanding the facts about Type 3B coveralls can prevent misunderstandings:

1. "All Coveralls are the Same"

This is a common misconception. Type 3B coveralls are specifically designed for liquid chemical protection, whereas other coveralls may not offer the same level of safety.

2. "Breathability Compromises Protection"

While some may believe that breathable materials sacrifice protection, advances in technology have led to materials that provide both comfort and safety effectively.

3. "Type 3B Coveralls are Only for Industrial Use"

Type 3B coveralls are versatile and can be used in various settings, including healthcare and cleaning, making them beneficial for numerous industries.

Frequently Asked Questions

1. What does Type 3B mean in coveralls?

Type 3B indicates that the coveralls provide protection against liquid chemicals and meet specific safety standards for liquid penetration resistance.

2. Are Type 3B coveralls reusable?

It depends on the material. Some Type 3B coveralls are designed for single use, while others can be cleaned and reused. Always check the manufacturer's guidelines.

3. How do I know which size coveralls to choose?

Refer to the manufacturer’s sizing chart for accurate measurements. Ensure that the coveralls fit comfortably while allowing for ease of movement.

4. Can Type 3B coveralls protect against all chemicals?

No, Type 3B coveralls are designed for specific liquid chemical protection. Always assess the chemicals present in your workplace to choose the right protective gear.

5. How long do Type 3B coveralls last?

The lifespan of Type 3B coveralls depends on the material, frequency of use, and proper care. Regular inspections and maintenance can extend their usability.

Conclusion

Selecting the right Type 3B coveralls is crucial for ensuring the safety and comfort of workers in environments exposed to hazardous liquids. By understanding the key features, materials, applications, and selection criteria, employers can make informed decisions that protect their workforce. Regular maintenance and attention to industry standards further enhance the effectiveness of these coveralls, making them an indispensable part of personal protective equipment.

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation