Understanding the Benefits of Microporous Film Laminates in Coveralls

2025-05-06

Microporous film laminates are an advanced material innovation widely used in the production of coveralls, particularly in the hygiene and cleaning sectors. These laminates are designed to provide an effective barrier against liquids and particulate matter while maintaining breathability, making them an ideal choice for personal protective equipment (PPE) in various environments.

One of the primary benefits of microporous film laminates is their excellent waterproofing properties. The microporous structure allows for the exclusion of water, ensuring that the wearer remains dry and comfortable in wet conditions. This characteristic is particularly beneficial for those working in cleaning and sanitation, where exposure to fluids is common. In addition, since these materials are also resistant to certain chemicals, they provide an added layer of protection for professionals handling various cleaning agents.

Another significant advantage of coveralls made from microporous film laminates is their breathability. Unlike some traditional waterproof materials, microporous films allow moisture vapor to escape, reducing the risk of overheating and discomfort. This is essential for workers who may wear these coveralls for extended periods. The combination of liquid resistance and breathability ensures comfort without compromising safety.

Durability is another critical factor when it comes to microporous film laminates. These materials are engineered to withstand wear and tear in challenging environments, ensuring that coveralls maintain their protective qualities over time. The robustness of these laminates means that they can endure the rigors of various cleaning tasks without losing their effectiveness.

Moreover, the lightweight nature of microporous film laminates contributes to the overall comfort of coveralls. Heavy and bulky protective gear can hinder movement and reduce efficiency. In contrast, garments made from these advanced materials provide flexibility while still delivering the necessary protection, allowing workers to perform their tasks with ease.

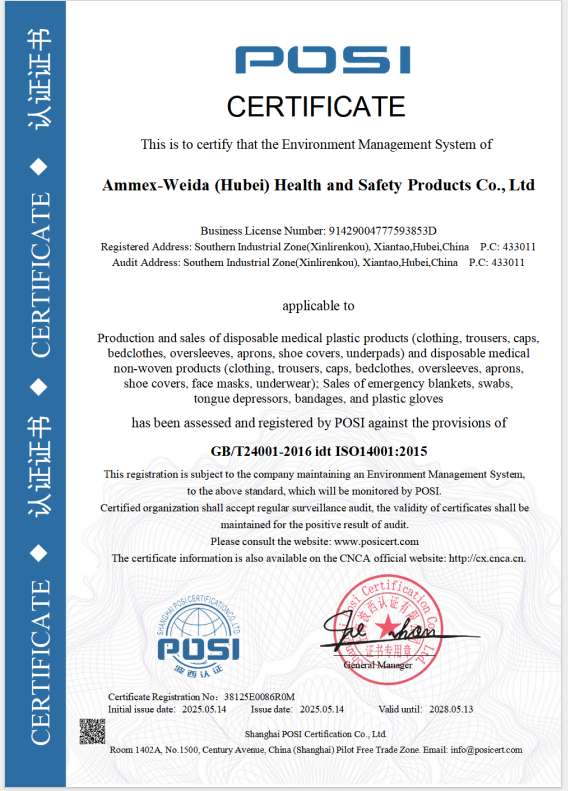

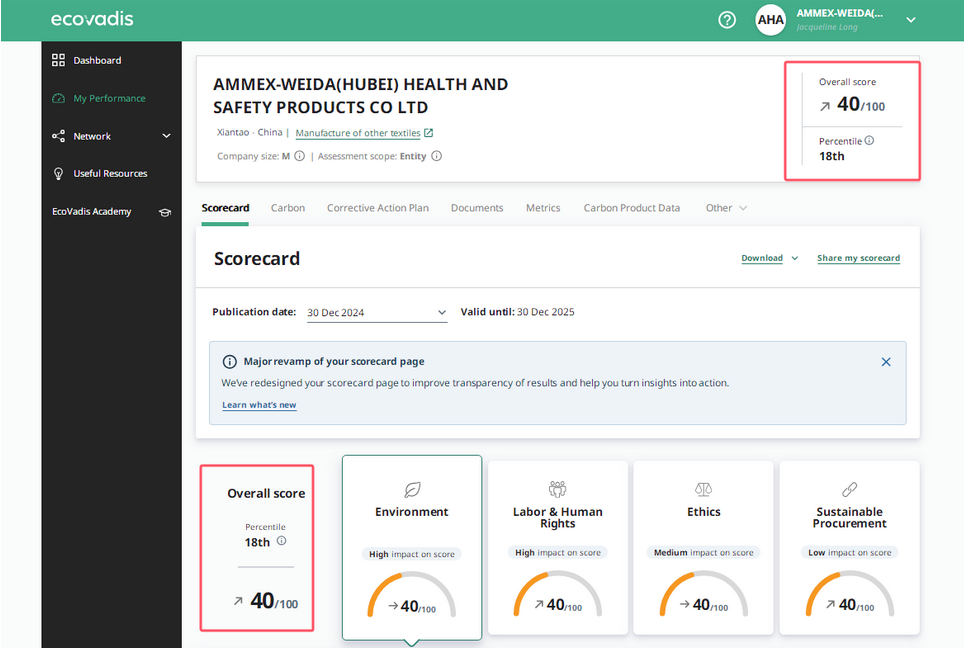

The environmental impact of using microporous film laminates is also worth considering. Many manufacturers are now focusing on creating sustainable options that minimize ecological footprints. By choosing coveralls made from these innovative materials, companies can enhance their sustainability initiatives while ensuring the safety and comfort of their employees.

In summary, microporous film laminates are revolutionizing the design of coveralls in the hygiene and cleaning industry. Their waterproofing ability, breathability, durability, lightweight nature, and potential for sustainability make them a superb choice for those seeking reliable protective gear. As the demand for effective and comfortable PPE continues to rise, understanding the advantages of microporous film laminates will be essential for making informed decisions in the market.

One of the primary benefits of microporous film laminates is their excellent waterproofing properties. The microporous structure allows for the exclusion of water, ensuring that the wearer remains dry and comfortable in wet conditions. This characteristic is particularly beneficial for those working in cleaning and sanitation, where exposure to fluids is common. In addition, since these materials are also resistant to certain chemicals, they provide an added layer of protection for professionals handling various cleaning agents.

Another significant advantage of coveralls made from microporous film laminates is their breathability. Unlike some traditional waterproof materials, microporous films allow moisture vapor to escape, reducing the risk of overheating and discomfort. This is essential for workers who may wear these coveralls for extended periods. The combination of liquid resistance and breathability ensures comfort without compromising safety.

Durability is another critical factor when it comes to microporous film laminates. These materials are engineered to withstand wear and tear in challenging environments, ensuring that coveralls maintain their protective qualities over time. The robustness of these laminates means that they can endure the rigors of various cleaning tasks without losing their effectiveness.

Moreover, the lightweight nature of microporous film laminates contributes to the overall comfort of coveralls. Heavy and bulky protective gear can hinder movement and reduce efficiency. In contrast, garments made from these advanced materials provide flexibility while still delivering the necessary protection, allowing workers to perform their tasks with ease.

The environmental impact of using microporous film laminates is also worth considering. Many manufacturers are now focusing on creating sustainable options that minimize ecological footprints. By choosing coveralls made from these innovative materials, companies can enhance their sustainability initiatives while ensuring the safety and comfort of their employees.

In summary, microporous film laminates are revolutionizing the design of coveralls in the hygiene and cleaning industry. Their waterproofing ability, breathability, durability, lightweight nature, and potential for sustainability make them a superb choice for those seeking reliable protective gear. As the demand for effective and comfortable PPE continues to rise, understanding the advantages of microporous film laminates will be essential for making informed decisions in the market.

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation