Exploring the Versatility of Microporous Film Laminates in Coverall Design

2025-04-11

Exploring the Versatility of Microporous Film Laminates in Coverall Design

Table of Contents

- 1. Introduction to Microporous Film Laminates

- 2. Key Properties of Microporous Film Laminates

- 3. Benefits of Using Microporous Film Laminates in Coveralls

- 4. Applications of Microporous Film Laminates in Various Industries

- 5. Designing Coveralls with Microporous Film Laminates

- 6. Sustainability Aspects of Microporous Film Laminates

- 7. Future Trends in Microporous Film Laminate Technology

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Microporous Film Laminates

Microporous film laminates have emerged as a transformative material in the design of coveralls, particularly in industries requiring protective clothing. These laminates consist of a unique structure that combines a microporous film with a variety of substrates, resulting in a lightweight yet durable fabric. The microporous nature allows for breathability while providing excellent protection against liquids and particulates. As we explore the versatility of these materials, it becomes clear that they are not merely an option but a game-changer in coverall design.

2. Key Properties of Microporous Film Laminates

Understanding the properties of microporous film laminates is crucial to appreciating their role in coverall design. Here are the primary characteristics that make them ideal for protective clothing:

2.1 Breathability

Breathability is one of the standout features of microporous film laminates. The tiny pores in the film allow moisture vapor to escape, keeping the wearer comfortable even during strenuous activities. This is particularly important in environments where temperature regulation is essential.

2.2 Liquid Resistance

Microporous films are designed to repel liquids, ensuring that wearers remain dry in wet conditions. This property is vital in industries such as healthcare and manufacturing, where exposure to harmful substances is a concern.

2.3 Lightweight and Flexible

Unlike traditional protective fabrics, microporous film laminates are lightweight and flexible, allowing for greater freedom of movement. This flexibility enhances the overall comfort of the coveralls, making them suitable for extended wear.

2.4 Durability and Resistance

These laminates are not only resistant to water but also to abrasion and tearing. The durability of microporous film laminates means that coveralls made from these materials can withstand harsh working conditions, providing long-lasting protection.

3. Benefits of Using Microporous Film Laminates in Coveralls

The integration of microporous film laminates into coverall design brings numerous benefits to various industries.

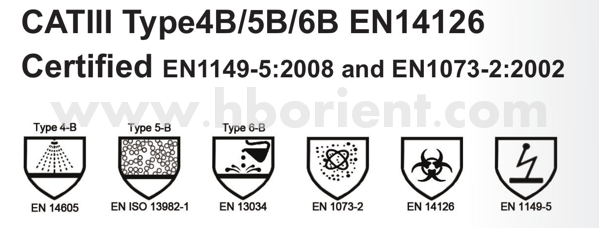

3.1 Enhanced Worker Safety

The ability of these laminates to protect against chemicals and biological agents is crucial in ensuring worker safety. For instance, healthcare professionals and laboratory workers benefit significantly from coveralls designed with microporous film, as these garments offer essential protection against spills and splashes.

3.2 Improved Comfort and Performance

Coveralls crafted from microporous film laminates provide a comfortable fit and maintain breathability, which is essential for maintaining focus and efficiency on the job. Workers experience less fatigue due to the enhanced comfort level, ultimately leading to better performance.

3.3 Cost-Effectiveness

While the initial investment in microporous film laminate coveralls might be higher than traditional options, the long-term cost savings are significant. The durability of these materials reduces the need for frequent replacements, saving money over time.

3.4 Versatile Design Options

Microporous film laminates can be combined with various fabrics and styles, allowing for customized coveralls that meet the specific needs of different industries. Whether for aesthetic purposes or functional requirements, the design versatility of these laminates is unparalleled.

4. Applications of Microporous Film Laminates in Various Industries

Microporous film laminates are making strides in a range of industries, providing innovative solutions for protective clothing.

4.1 Healthcare Industry

In healthcare, the need for protective clothing is paramount. Microporous film laminates are used in surgical gowns, isolation gowns, and coveralls, providing healthcare workers with the protection they need from pathogens and harmful substances.

4.2 Manufacturing and Construction

Workers in manufacturing and construction face exposure to various hazards, including chemicals, dust, and extreme temperatures. Microporous film laminate coveralls offer an effective barrier against these dangers while maintaining breathability and comfort.

4.3 Hazardous Material Handling

For workers dealing with hazardous materials, protective clothing made from microporous film laminates is essential. These coveralls provide a secure barrier against chemical splashes and particulate matter, ensuring safety in high-risk environments.

4.4 Environmental Applications

In environmental cleanup operations, coveralls made from microporous film laminates protect workers from contaminants. The lightweight and durable nature of these materials makes them ideal for long hours spent in potentially hazardous conditions.

5. Designing Coveralls with Microporous Film Laminates

The design process of coveralls utilizing microporous film laminates involves careful consideration of several factors to maximize protection, comfort, and functionality.

5.1 Customization and Fit

Each industry has specific requirements for protective clothing. The ability to customize coveralls using microporous film laminates ensures that they meet the unique demands of various job roles, providing a snug yet comfortable fit.

5.2 Integration of Additional Features

Designers often integrate features such as hoods, cuffs, and elastic waistbands to enhance the protective qualities of the coveralls. These added elements work in conjunction with the microporous film laminates to deliver superior safety.

5.3 Color and Visibility

In high-risk environments, visibility is crucial. Incorporating bright colors and reflective strips into the design of microporous film laminate coveralls can enhance safety by making workers more visible to others.

6. Sustainability Aspects of Microporous Film Laminates

As industries increasingly prioritize sustainability, microporous film laminates present a favorable eco-friendly option.

6.1 Reduced Waste

The durability of microporous film laminates means longer-lasting products, which contributes to reduced textile waste in landfills. Additionally, many manufacturers are adopting sustainable practices in the production of these materials.

6.2 Recyclability

Some microporous film laminates are designed to be recyclable, further enhancing their environmental appeal. As recycling technology progresses, the industry is moving towards creating closed-loop systems for protective clothing.

7. Future Trends in Microporous Film Laminate Technology

The future of microporous film laminates is promising, with several trends emerging that could further enhance their application in coverall design.

7.1 Smart Fabrics Integration

Innovations in smart fabrics could revolutionize how microporous film laminates are used in protective clothing. Features such as temperature regulation and moisture-wicking technology could be integrated into coverall designs.

7.2 Advanced Testing Procedures

As industries evolve, so too will the testing standards for protective clothing. Future developments may include more rigorous testing of microporous film laminates to ensure the highest safety standards are met.

8. Frequently Asked Questions

8.1 What are microporous film laminates?

Microporous film laminates are advanced materials that combine a microporous film with various substrates, offering unique properties such as breathability, liquid resistance, and durability.

8.2 How do microporous film laminates improve comfort in coveralls?

They allow moisture vapor to escape while preventing liquid penetration, which helps maintain a comfortable microclimate for the wearer.

8.3 In which industries are microporous film laminates used?

They are widely used in healthcare, manufacturing, construction, hazardous material handling, and environmental cleanup.

8.4 Are microporous film laminates eco-friendly?

Yes, many microporous film laminates are designed to be durable and recyclable, contributing to reduced waste and promoting sustainable practices in manufacturing.

8.5 What features can enhance the safety of microporous film laminate coveralls?

Features such as hoods, elastic cuffs, reflective strips, and customizable fits can significantly enhance the protective qualities and visibility of coveralls.

9. Conclusion

Microporous film laminates are revolutionizing the design and functionality of coveralls in various industries. Their unique properties, combined with their versatility and sustainability, make them a preferred choice for protective clothing. As technology continues to advance, we can expect even more innovative applications and improvements in microporous film laminate technology, ensuring that worker safety and comfort remain a top priority. Embracing these materials will not only enhance protection but also contribute to a more sustainable future in protective clothing design.

Latest News

Quick Navigation

Ammex-Weida(Hubei) Health and Safety Products Co.,Ltd (Chinese Version)

Contact Us

5F,BLDG No.8,SOHO Town,CBD,Huaihai Road,Jianghan District,Wuhan,Hubei,China

Copyright © Hubei Orient International Trading Corporation